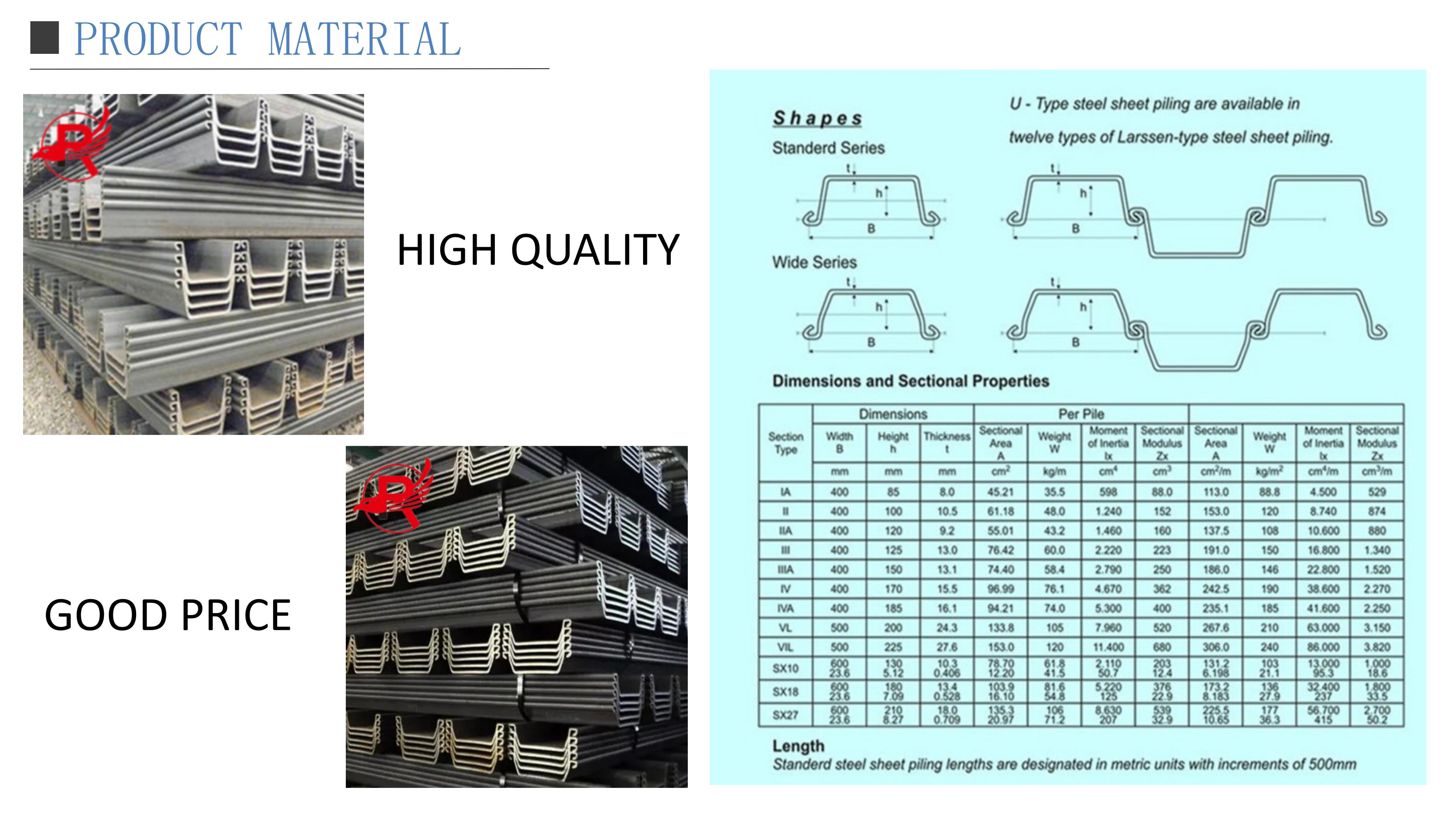

Гарячекатана U-подібна сталева шпунтова паля з водонепроникним покриттям

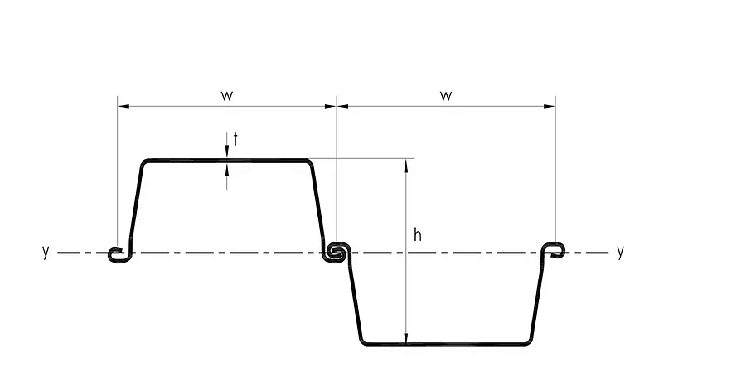

РОЗМІР ПРОДУКТУ

| ТЕХНІЧНІ ХАРАКТЕРИСТИКИ ДО ШПУНТОВОЇ ПАЛІ | |

| 1. Розмір | 1) 400*100 - 600*210 мм |

| 2) Товщина стінки: 10,5-27,6 мм | |

| 3) U-подібний шпунт | |

| 2. Стандарт: | JIS A5523, JIS A5528 |

| 3. Матеріал | SY295, SY390, S355 |

| 4. Розташування нашої фабрики | Шаньдун, Китай |

| 5. Використання: | 1) земляна підпірна стіна |

| 2) будівництво конструкції | |

| 3) огорожа | |

| 6. Покриття: | 1) Оголений2) Чорне фарбування (лакове покриття)3) оцинкований |

| 7. Техніка: | гарячекатаний |

| 8. Тип: | U-подібний шпунт |

| 9. Форма перерізу: | U |

| 10. Інспекція: | Перевірка клієнтом або перевірка третьою стороною. |

| 11. Доставка: | Контейнер, судно для насипних вантажів. |

| 12. Про нашу якість: | 1) Без пошкоджень, без зігнутості2) Без змащення та маркування3) Всі товари можуть бути перевірені сторонньою інспекцією перед відправкою |

| Розділ | Ширина | Висота | Товщина | Площа поперечного перерізу | Вага | Модуль пружності перерізу | Момент інерції | Площа покриття (з обох сторін на ворсу) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (в) | (год) | Фланець (tf) | Веб (tw) | На палю | Пер Волл | |||||

| mm | mm | mm | mm | см2/м | кг/м | кг/м2 | см3/м | см4/м | м2/м | |

| Тип II | 400 | 200 | 10.5 | - | 152,9 | 48 | 120 | 874 | 8 740 | 1.33 |

| Тип III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1340 | 16 800 | 1.44 |

| Тип IIIA | 400 | 300 | 13.1 | - | 186 | 58,4 | 146 | 1520 | 22 800 | 1.44 |

| Тип IV | 400 | 340 | 15,5 | - | 242 | 76.1 | 190 | 2270 | 38 600 | 1.61 |

| Тип VL | 500 | 400 | 24.3 | - | 267,5 | 105 | 210 | 3150 | 63 000 | 1,75 |

| Тип IIw | 600 | 260 | 10.3 | - | 131.2 | 61,8 | 103 | 1000 | 13 000 | 1,77 |

| Тип IIIw | 600 | 360 | 13.4 | - | 173.2 | 81,6 | 136 | 1800 | 32 400 | 1.9 |

| Тип IVw | 600 | 420 | 18 | - | 225,5 | 106 | 177 | 2700 | 56 700 | 1,99 |

| Тип VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3 820 | 86 000 | 1.82 |

*Надішліть електронного листа на адресу[електронна адреса захищена]щоб отримати цінову пропозицію на ваші проекти

Діапазон модулів перерізу

1100-5000 см³/м

Діапазон ширини (одинарний)

580-800 мм

Діапазон товщини

5-16 мм

Виробничі стандарти

BS EN 10249 Частина 1 та 2

Марки сталі

SY295, SY390 та S355GP для типів II та VIL

S240GP, S275GP, S355GP та S390 для VL506A–VL606K

Довжина

максимум 27,0 м

Стандартна довжина 6 м, 9 м, 12 м, 15 м

Варіанти доставки

Одинарні або парні

Пари вільні, зварні або обтиснуті

Підйомний отвір

Контейнером (11,8 м або менше) або насипом

Покриття для захисту від корозії

ОСОБЛИВОСТІ

1. Висока міцність: U-подібні сталеві шпунтові палі виготовляються з високоякісної сталі, що забезпечує чудову міцність і жорсткість. Це дозволяє їм витримувати великі навантаження, тиск ґрунту та тиск води.

2. Універсальність:Шпунтова паля 500 x 200 uможуть використовуватися в широкому спектрі застосувань, включаючи підпірні стіни, кесони та опори фундаментів. Вони також підходять для використання як у постійних, так і в тимчасових конструкціях.

3. Ефективне встановлення: Ці шпунтові палі розроблені з системами з'єднання, що забезпечують швидке та ефективне встановлення. Система з'єднання дозволяє щільно з'єднувати палі разом, забезпечуючи стійкість та запобігаючи протіканню ґрунту чи води.

4. Відмінна довговічність: U-подібні сталеві шпунтові палі мають високу стійкість до корозії та можуть витримувати екстремальні погодні умови, що робить їх придатними для тривалого використання в різних середовищах. Їх також можна покривати або обробляти для підвищення довговічності та захисту від корозії.

5. Легке обслуговування: Технічне обслуговування U-подібних сталевих шпунтових паль зазвичай мінімальне. Будь-який необхідний ремонт або технічне обслуговування часто можна виконати без необхідності проведення великих земляних робіт або порушення навколишніх конструкцій.

6. Економічно ефективні: U-подібні сталеві шпунтові палі пропонують економічно ефективне рішення для багатьох будівельних проектів. Вони забезпечують тривалий термін служби, потребують мінімального обслуговування, а їх встановлення може бути ефективним, що дозволяє потенційно заощадити кошти.

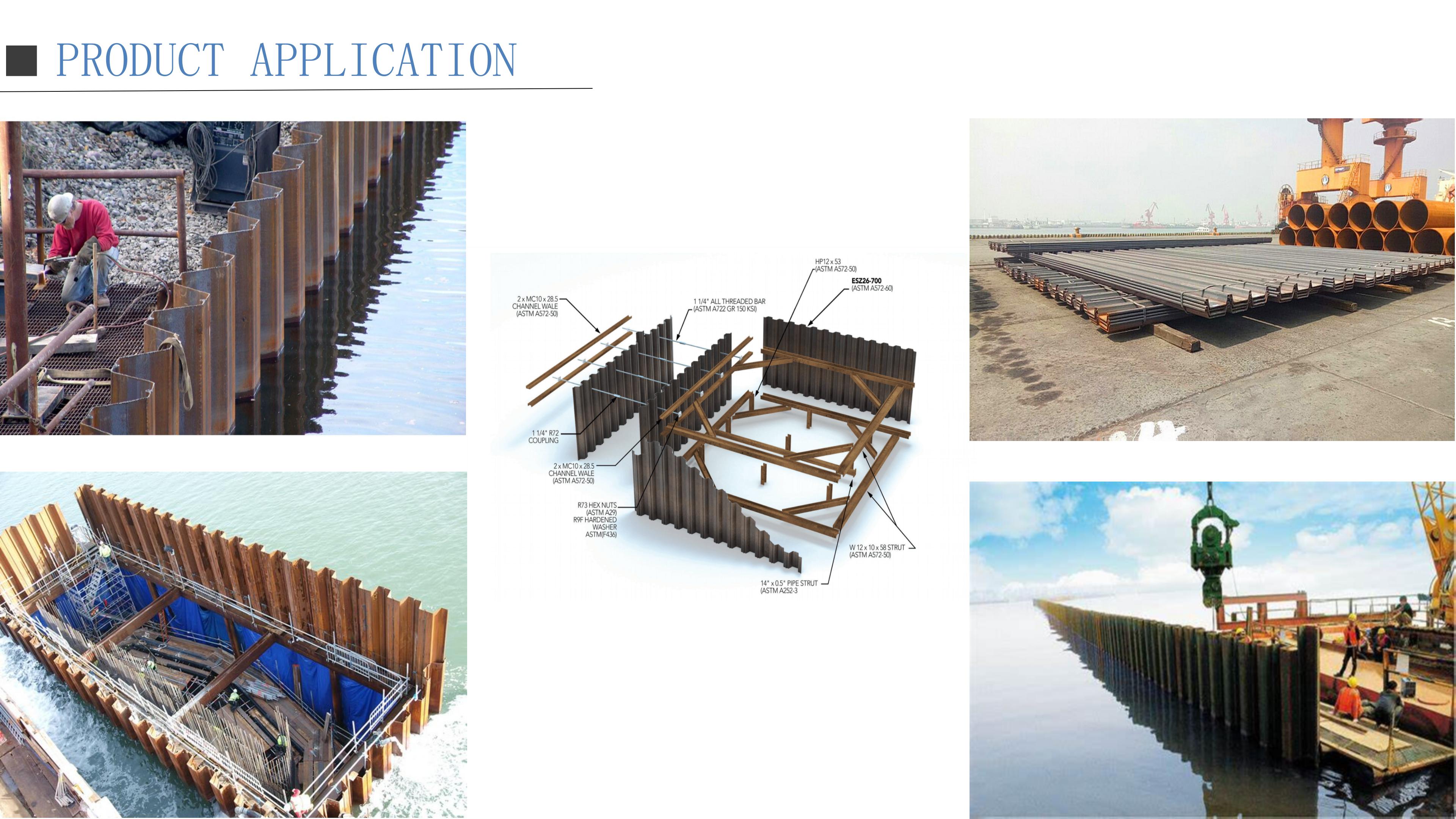

ЗАСТОСУВАННЯ

фундаментні палімають широкий спектр застосування в різних галузях промисловості та будівельних проектах. Деякі з поширених застосувань включають:

Підпірні стіни: U-подібні сталеві шпунтові палі широко використовуються для будівництва підпірних стін для підтримки тиску ґрунту або води. Вони забезпечують стійкість та запобігають ерозії ґрунту, що робить їх придатними для інфраструктурних проектів, таких як опори мостів, підземні паркувальні споруди та забудови набережної.

Кесони та відсікаючі стіни: U-подібні сталеві шпунтові палі використовуються для будівництва тимчасових або постійних кесонів у водоймах. Вони створюють бар'єр для зневоднення території, дозволяючи проводити будівельні роботи без проникнення води. Їх також використовують як відсікаючі стіни для блокування потоку води та контролю рівня ґрунтових вод на будівельних майданчиках.

Системи глибокого фундаменту: U-подібні сталеві шпунтові палі використовуються як частина систем глибокого фундаменту, таких як комбіновані стіни та стіни з шламу, для підтримки котлованів та стабілізації ґрунту. Вони можуть виступати як тимчасове або постійне рішення, залежно від вимог проекту.

Захист від повеней: U-подібні сталеві шпунтові палі використовуються для запобігання повеням у низинних районах. Їх можна встановлювати вздовж берегів річок, узбережжя або прибережних зон для забезпечення армування та опору потоку води, захищаючи навколишню інфраструктуру та майно.

Морські споруди: U-подібні сталеві шпунтові палі широко використовуються в будівництві різних морських споруд, включаючи морські дамби, хвилерізи, пристані та поромні термінали. Вони забезпечують стійкість та захищають від ерозії, спричиненої хвилями та течіями в прибережних районах.

Підземні споруди: U-подібні сталеві шпунтові палі використовуються для стабілізації котлованів підземних споруд, таких як підвали, підземні паркінги та тунелі. Вони забезпечують тимчасову або постійну підтримку для запобігання обваленню ґрунту та забезпечення безпеки під час будівництва.

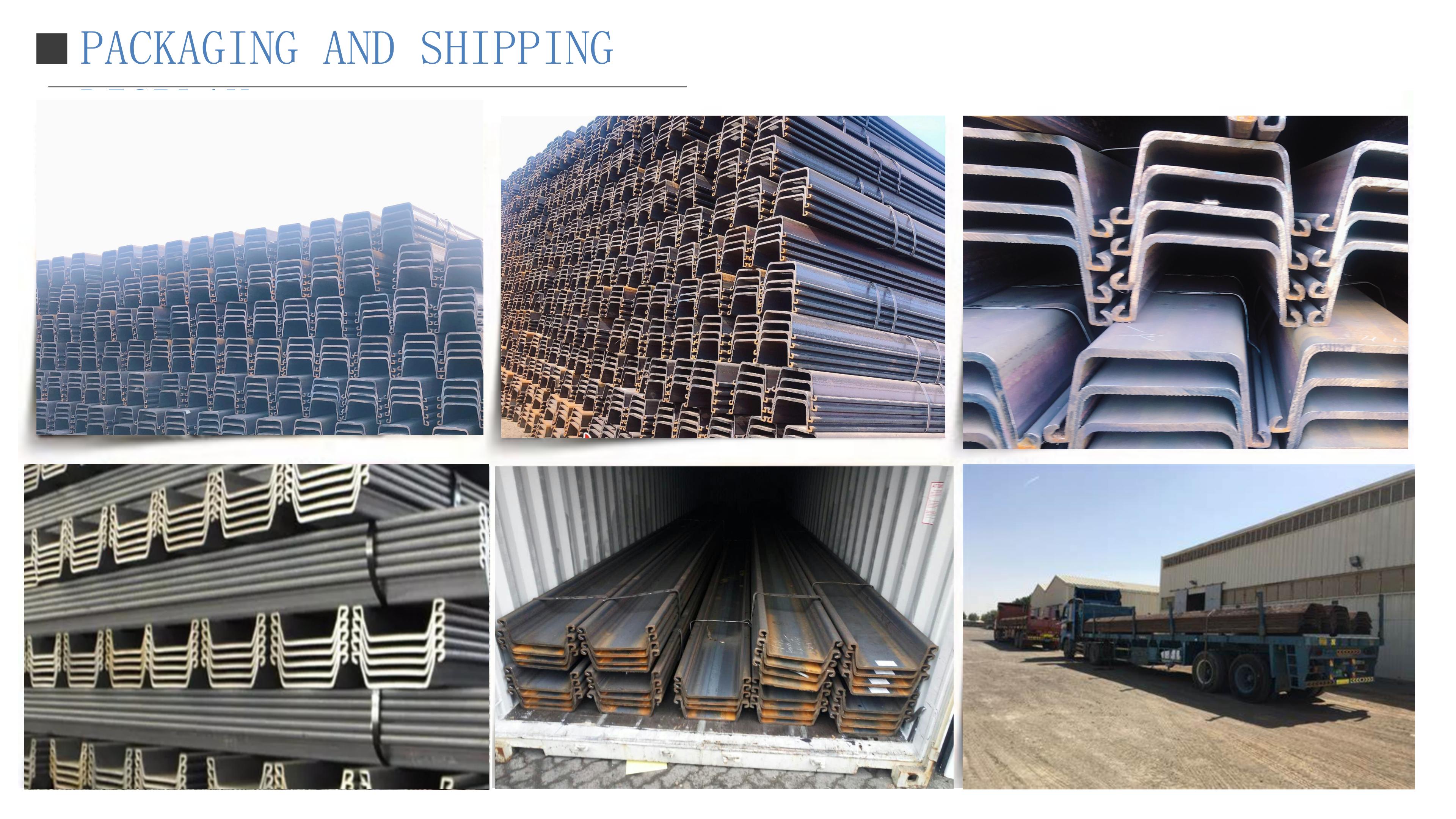

УПАКОВКА ТА ДОСТАВКА

Упаковка:

металевий шпунтБезпечно: Розташуйте U-подібні шпунти в акуратний та стійкий штабель, переконавшись, що вони правильно вирівняні, щоб запобігти будь-якій нестабільності. Використовуйте обв'язки або стрічки, щоб закріпити штабель та запобігти зміщенню під час транспортування.

Використовуйте захисні пакувальні матеріали: обгорніть стопку шпунтів вологостійким матеріалом, таким як пластик або водонепроникний папір, щоб захистити їх від впливу води, вологості та інших факторів навколишнього середовища. Це допоможе запобігти іржі та корозії.

Доставка:

Виберіть відповідний вид транспорту: залежно від кількості та вагипалюче покриттявідповідний вид транспорту, такий як вантажівки з плоскими платформами, контейнери або кораблі. Враховуйте такі фактори, як відстань, час, вартість та будь-які нормативні вимоги до транспортування.

Використовуйте відповідне підйомне обладнання: Для завантаження та розвантаження U-подібних сталевих шпунтів використовуйте відповідне підйомне обладнання, таке як крани, вилкові навантажувачі або навантажувачі. Переконайтеся, що обладнання, що використовується, має достатню вантажопідйомність для безпечного перенесення ваги шпунтів.

Закріплення вантажу: належним чином закріпіть упакований штабель шпунтових паль на транспортному засобі за допомогою ременів, кріплень або інших відповідних засобів, щоб запобігти зміщенню, ковзанню або падінню під час транспортування.

СИЛА КОМПАНІЇ

Зроблено в Китаї, першокласний сервіс, передова якість, всесвітньо відоме

1. Ефект масштабу: Наша компанія має великий ланцюг поставок та великий сталеливарний завод, досягаючи ефекту масштабу в транспортуванні та закупівлях, і стаючи сталеливарною компанією, яка інтегрує виробництво та послуги

2. Різноманітність продукції: Різноманітність продукції, будь-яку сталь, яку ви хочете, можна придбати у нас, в основному займаючись сталевими конструкціями, сталевими рейками, сталевими шпунтами, фотоелектричними кронштейнами, швелерною сталлю, кремнієвими сталевими рулонами та іншими виробами, що робить його більш гнучким. Виберіть потрібний тип продукції для задоволення різних потреб.

3. Стабільні постачання: Наявність стабільнішої виробничої лінії та ланцюга поставок може забезпечити надійніше постачання. Це особливо важливо для покупців, яким потрібні великі обсяги сталі.

4. Вплив бренду: Мають більший вплив бренду та більший ринок

5. Сервіс: Велика сталеливарна компанія, яка об'єднує налаштування, транспортування та виробництво

6. Конкурентоспроможність цін: розумна ціна

*Надішліть електронного листа на адресу[електронна адреса захищена]щоб отримати цінову пропозицію на ваші проекти

ВІЗИТ КЛІЄНТІВ

Коли клієнт бажає ознайомитися з товаром, зазвичай можна організувати такі кроки:

Заплануйте візит: Клієнти можуть заздалегідь зв’язатися з виробником або торговим представником, щоб домовитися про час і місце для ознайомлення з продуктом.

Організуйте екскурсію: Залучіть фахівців або торгових представників як гідів, щоб показати клієнтам виробничий процес, технології та процес контролю якості продукту.

Демонстрація продукції: Під час візиту демонструйте клієнтам продукцію на різних етапах, щоб вони могли зрозуміти виробничий процес та стандарти якості продукції.

Відповідайте на запитання: Під час візиту у клієнтів можуть виникати різні запитання, і екскурсовод або торговий представник повинен терпляче на них відповідати та надавати відповідну технічну та якісну інформацію.

Надання зразків: Якщо можливо, зразки продукції можна надавати клієнтам, щоб клієнти могли інтуїтивніше зрозуміти якість та характеристики продукту.

Подальші дії: Після візиту оперативно реагуйте на відгуки клієнтів та надавайте клієнтам подальшу підтримку та послуги.

Найчастіші запитання

1. Як я можу отримати від вас цінову пропозицію?

Ви можете залишити нам повідомлення, і ми вчасно відповімо на кожне повідомлення.

2. Чи доставите ви товар вчасно?

Так, ми обіцяємо надавати продукцію найвищої якості та доставку вчасно. Чесність – це принцип нашої компанії.

3. Чи можу я отримати зразки перед замовленням?

Так, звичайно. Зазвичай наші зразки безкоштовні, ми можемо виготовити за вашими зразками або технічними кресленнями.

4. Які ваші умови оплати?

Наш звичайний термін оплати - 30% депозит, а решта - на рахунок B/L. EXW, FOB, CFR, CIF.

5. Чи приймаєте ви перевірку третьою стороною?

Так, безумовно, ми приймаємо.

6. Як ми можемо довіряти вашій компанії?

Ми роками спеціалізуємося на сталеливарному бізнесі як золотий постачальник, штаб-квартира знаходиться в провінції Тяньцзінь, ласкаво просимо до розслідування будь-якими способами, будь ласка.